We manufacture the majority of our products from aluminium. The material is easy to process, has a low density and is corrosion resistant. Furthermore, aluminium is very easy to recycle.

On request, we can also manufacture your aluminium profile with an anodised finish or other suitable surface finish. In production engineering and with corresponding batch sizes, we work with specially developed special machines to ensure the highest quality and precision for every aluminium profile.

Do you just need a single aluminium profile? No problem – we also produce one-off parts. Just contact us with your requirements.

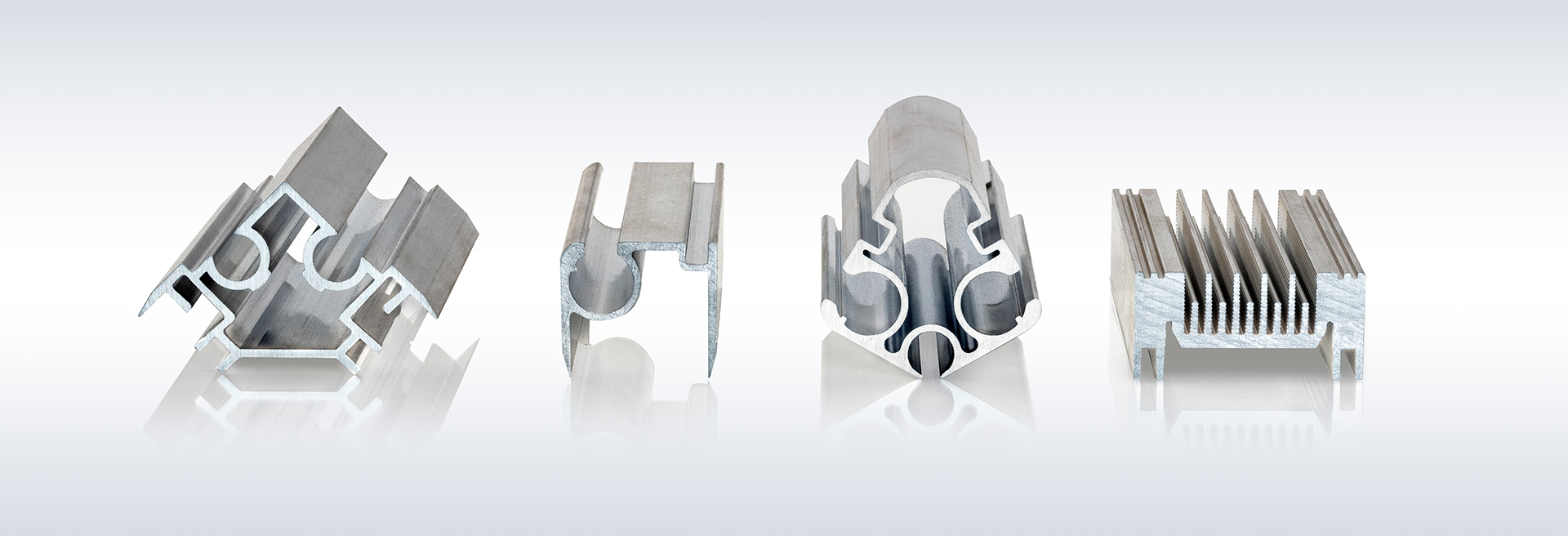

IsoProfil is specialised on extruded-alu-profile. Any extruded profile is formed by materiel pushed through a die by using a stamp. We divide in direct and indirect operation. The indirect extrusion means In the field of extrusion we reach an exceptionally high precision , which is above the standards DIN EN 12020-2 and DIN EN 755-9. With innovative technology we work, depending on the profile geomertry, with tolerances down to ± 0.01 mm and offer any desired extruded in various shapes and sizes and optimum surface finish. Other Materials such as brass or copper and as well as magnesium can be manufactured too.

In view of its high corrosion resistance, low density and the fact that it is easy to process, aluminium can be used in a wide range of applications and is therefore our most popular material for our profiles.

Monitor housings

Spacers for insulated glazings

Flame protection

Conductive wires

Cooling plates for accumulators

Housings for motors in electric vehicles

Heat sinks

Individually manufactured custom profiles

IsoProfil can refine the surfaces of your aluminium profiles by means of electrochemical processes. These include, for example, anodising and galvanising.

During anodising, the outermost metal layer is converted into an oxide or hydroxide to form a thin, glass-hard coating that protects the underlying layers from corrosion and other external, predominantly mechanical influences.

Furthermore, anodising also offers numerous additional design options for aluminium profiles, such as different colour finishes. A galvanic coating of aluminium is also possible. Further possibilities of surface finishing include painting, powder coating and gilding.

|

Material number |

ASW 205 |

ASW 209 |

ASW 210 |

ASW 220 |

ASW 510 |

|

Material abbreviation (according to DIN EN) |

AlMgSi0,5 |

AlSiMg(A) |

AlSi1MgMn |

AlCu4Mg1 |

AlZnMgCu1,5 |

|

Alloy components in % |

Si 0,3 - 0,6 Fe 0,1 - 0,3 Cu 0,1 Mn 0,1 Mg 0,35 - 0,6 Zn 0,15 other 0,15 |

Si 0,5 - 0,9 Fe 0,35 Cu 0,3 Mn 0,5 Mg 0,4 - 0,7 Zn 0,7 other 0,15 |

Si 0,7 - 1,3 Fe 0,5 Cu 0,3 Mn 0,5 Mg 0,4 - 0,7 Zn 0,2 other 0,15 |

Si 0,5 Fe 0,5 Cu 3,8 - 4,9 Mn 0,3 - 0,9 Mg 1,2 - 1,8 Zn 0,25 other 0,15 |

Si 0,4 Fe 0,5 Cu 1,2 - 2 Mn 0,3 Mg 2,1 - 2,9 Zn 5,1 - 6,1 other 0,15 |

|

Density |

2,8 |

2,78 |

2,77 |

2,77 |

2,7 |

|

Properties 1. cold formability 2. hot formability 3. coating 4. protective anodizing 5. decorative anodizing 6. machinability 7. weldability 8. solderability 9. Corrosions resistance |

good good good good good good good good good |

sufficient good good good good good sufficient unsufficient good |

good good good good sufficient good good sufficient good |

sufficient sufficient sufficient good unsufficient good sufficient sufficient unsufficient |

unsufficient unsufficient sufficient sufficient unsufficient good sufficient unsufficient unsufficient |

|

Application possibilities |

mechanical-engineering automotive interior-contruction lighting industry |

automotive electrotechnology shipbuilding tank construction |

aviation structures machanical-engineering offshore industry shipbuilding |

aviation aerospace automotive machanical-engineering construction-industry |

machanical-engineering automotive aviation mold making tool making |

other alloys on request

Since steel is characterised by a higher density, and hence stronger and can withstand correspondingly higher loads, it requires far more intensive processing. Aluminium has a melting point of only 660°C, although it starts to soften at around 210°C. Steel, on the other hand, has to be heated to a temperature of 900-1500°C. In addition, aluminium also has a natural resistance to corrosion. Unlike steel which requires additional treatment, aluminium does not rust. Aluminium is therefore the more cost-efficient metal for profiles.

Aluminium is up to 100% recyclable and produces 92% less carbon dioxid than during the initial processing.

Learn more about the manufacturing processes we use