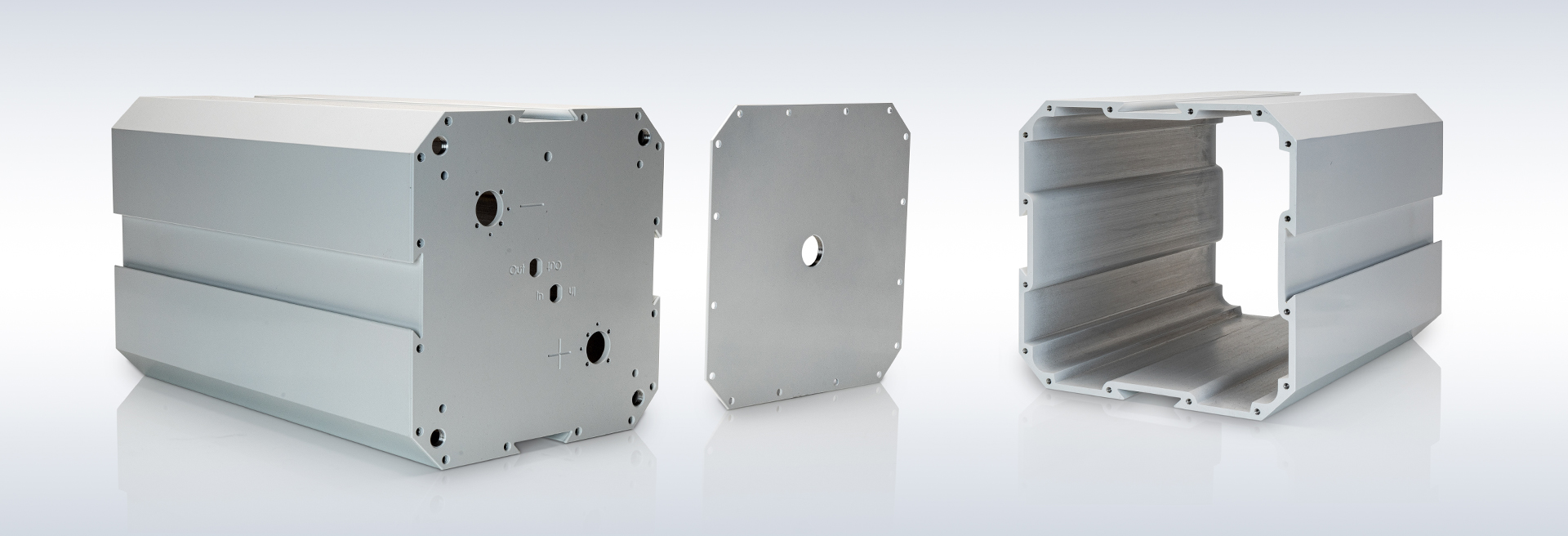

Our profile systems are available in a wide variety of different forms, such as extruded profiles, roll-profiled and rolled profiles, drawn, bent, surface finished or assembled. Our standard versions are:

The choice of the most suitable method depends on various factors - including the materials from which the profile systems are to be made, the field of application and the further processing possibilities.

We manufacture our profiles predominantly from aluminium, steel or stainless steel as well as brass and copper. Further materials, such as plastic or carbon, are also used, where necessary. Each material offers individual advantages. For example, an aluminium profile is highly corrosion-resistant, a stainless steel profile is particularly durable and a copper profile is electrically conductive. We will be happy to advise you on the various materials and to help you find the right profile system for your requirements.

Profile systems are increasingly being used in industry, machine engineering and automation thanks to their advantageous modular system. The resulting benefits are savings in planning, construction and assembly times.

Connecting elements

Securing of surface elements

Electrical installations

Partition wall systems

Protection systems

Supporting structures

As raw materials, extruded aluminium profiles are always more expensive than steel. So why are so many people switching to using aluminium profiles?

We generally used the aluminium profile for our profile systems, but we can also use other materials, depending on the customer's requirements.

Learn more about the manufacturing processes we use